In North America,

the use of stainless steel continues to grow in

popularity both inside and outside the home due to its many advantages.

Architects, engineers and contractors increasingly specify stainless steel

for use in construction, appliances, food processing equipment and the

medical field. As stainless steel usage continues to grow, proficiency in

finishing will take on increased importance.

For fabricators, the ability to proficiently fabricate and finish stainless

steel, can lead to both increased business and profitability. The most

effective fabricators follow a three step process for stainless steel finishing

projects. The first step involves working with the customer in order to

define and document the finish required for the project. Next the fab-

ricator must choose the correct abrasives and power tools that will be

used on the job to achieve the required finish. And finally, the fabricators

must create and execute the mechanical finishing process plan in order

to complete the project and satisfy the customer.

The first step

for fabricators

is to work with

each customer

to define the finish required. The finish for the base material and treat-

ment of the welds should be discussed and agreed upon. Generally, the

material finish is specified in grit (the particle size for the last step in

the abrasive finishing process). Stainless steel mate-

rial specifications are defined below.

Mechanical Finish Designations for

Steel Materials

#2D Finish

- a uniform, dull silver gray

mill finish that is applied to thinner stain-

less steel coils, the thickness of which has

been reduced by cold rolling.

#2B Finish

- A bright cold rolled mill

finish commonly produced in the same

manner as No. 2D, except that the final

light cold rolling pass is done using pol-

ished rolls.

#3 Finish

- A semi-polished surface

achieved by finishing with the equiva-

lent of a 80 to 120-grit abrasive. This

finish has a pronounced grit line.

·

·

·

Finish That Stainless Steel!

Once you reach agreement with a client on

a finish, it's important that you choose the

right materials, tools, and use the correct

technique for the finish type selected.

BY CHRIS STONE

step one

DEFINE THE FINISH

A sample swatch can be made out of tubing.

This sample shows a #7 finish, with welds

ground flus and pit and crevice free (similar

to NOMMA #1 finish).

Three steps to finishing

stainless steel:

Define

the finish

Choose

the right

abrasive

and power

tools

Finalize &

execute

the plan

#4 Finish

- Also called brushed, di-

rectional or satin finish A number 4

finish, characterized by fine polish-

ing grit lines that are uniform and

directional in appearance. The final

abrasive used in the process is 150 to

220 grit.

#6 Finish

- Polished finish achieved

with the equivalent of a 240-grit

abrasive. Finer grit lines and higher

reflectivity than n No. 4 finish.

#7 Finish

- Highly reflective sur-

face obtained with the equivalent

of a 320-grit abrasive. Minimal grit

lines.

#8 Finish

or Mirror Finish - pro-

duced by polishing with at least a

320 grit belt or wheel finish. The

part is then sisal and color buffed to

achieve a mirror-like finish.

Weld Treatment

The treatment of the welds should also be de-

fined with the customer. Weld treatment op-

tions are as follows;

Remove weld spatter and discoloration

only.

Remove weld spatter, discoloration and

weld ripple.

Remove weld spatter, discoloration and weld

ripple, plus grind weld smooth with base ma-

terial.

Remove weld spatter, discoloration and weld

ripple, plus grind weld smooth with base

material, and producing all welds pit and

crevice free.

·

·

·

·

1.

2.

3.

4.

Once the customer and fabricator have defined the material finish and weld

treatment, a sample swatch can be created to use as reference. The sample

swatch can be as simple as two pieces of stainless steel square tubing welded

together and finished per the aforementioned specifications.

Choosing Abrasives

Discs and belts are the most

popular abrasive mediums

for mechanical finishing of

stainless steel. Most often

abrasive discs are used for weld treatment, and belts are used for material

surface treatment. The one notable exception is the use of Dynafile small

portable belts for treating welds in hard to reach locations.

The following illustrates the typical mechanical finishing steps for weld

treatments along with the appropriate abrasive.

For removal of excess weld, spatter and discoloration, use the fol-

lowing abrasives:

For creating a uniform scratch pattern in weld, use

the following abrasives:

The advent of the flap disc has significantly reduced the steps

required for stainless steel finishing. In the past, operators

used a two step process for weld treatment consisting of a

grinding wheel for the first step (material removal) and then

resin fiber discfor the second step (uniform scratch pat-

tern).

Increasingly, the flap disc is replacing the older two-step

process with a single step, requiring only one abrasive prod-

uct. Layers of coated abrasive are arranged on a backing pad

in a fan like arrangement. In addition to reduced processing

times, flap discs are less prone to gouging and scratching the

work piece (very common with grinding wheels). Gouging

and scratching can significantly increase downstream polish-

ing times.

·

·

·

·

·

·

·

·

step two

CHOOSING ABRASIVES

AND POWER TOOLS

The sets of discs shown above in-

(LEFT)

,

(RIGHT)

.

Unitized discs

(PHOTO ABOVE)

.

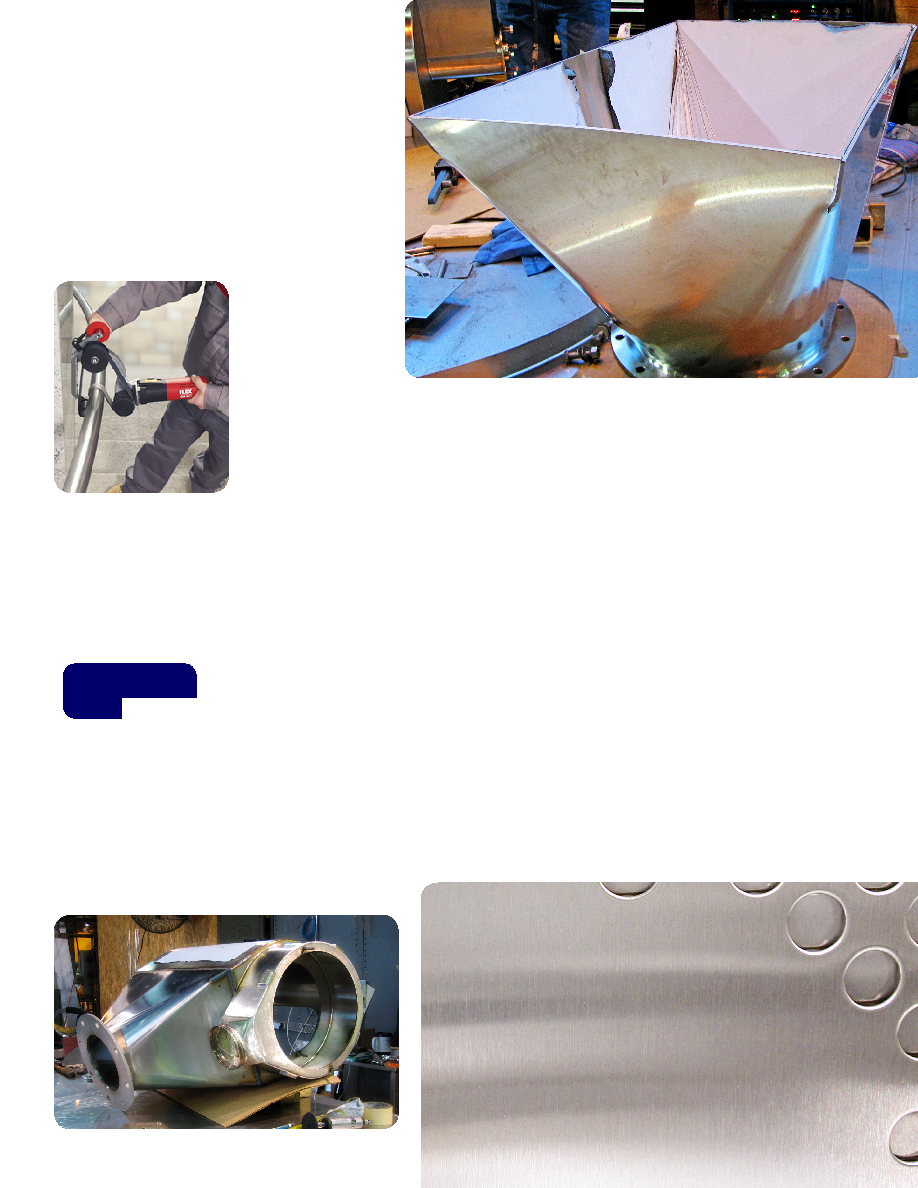

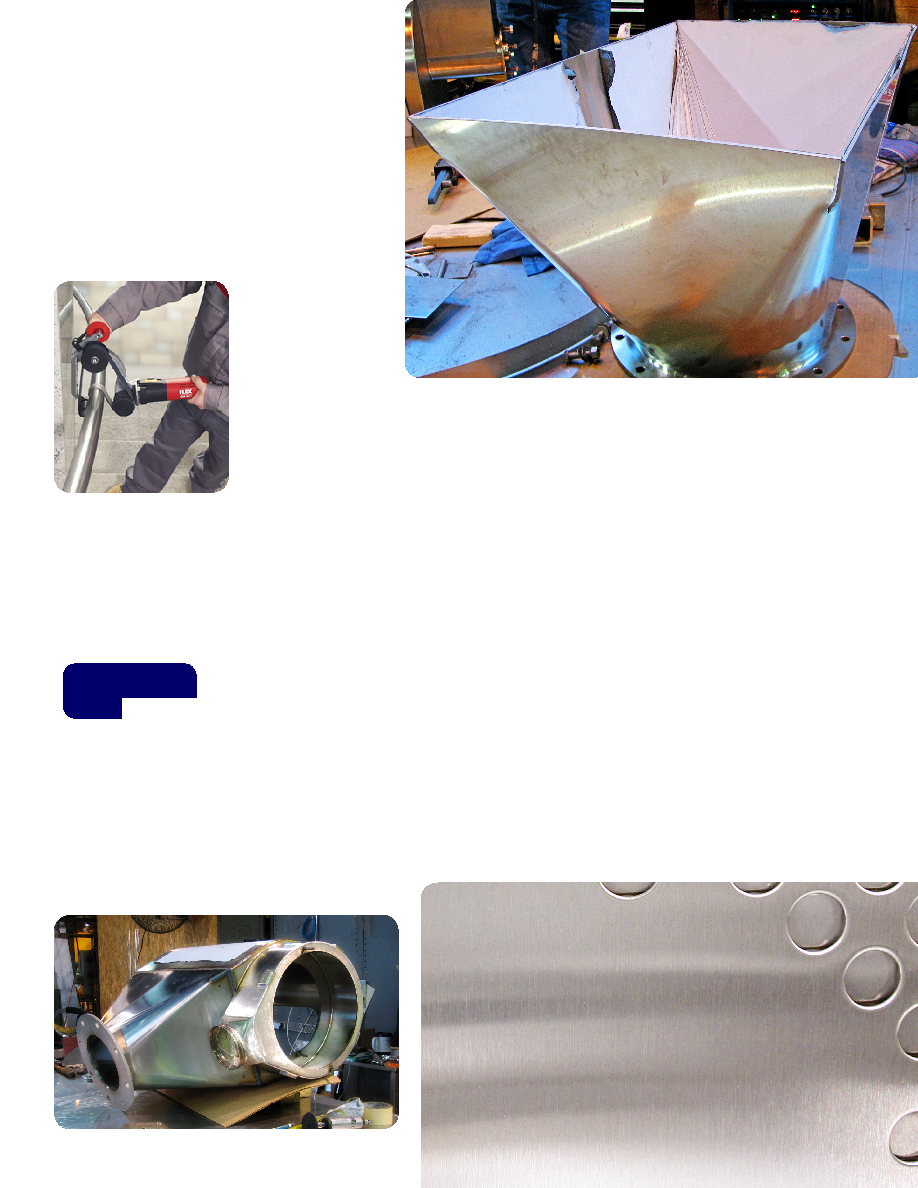

An employee is using a unitized disc to create a

#4 finish. Notice the operator's use of a protec-

tive rubber to prevent the material from scratching

during polishing.

For finer weld finishing, a bevy of new

products are now available that improve

surface finishes and reduce polishing

times. The newer products include sur-

face conditioning flap discs, combina-

tion flap discs, and unitized disc. Surface

conditioning material is a nylon web

impregnated with abrasive grit. The ma-

terial is available in coarse (50-80 grit),

medium (100-150 grit), fine (180-220

grit), and very fine (240 -360grit) and

produces a matte like finish when ap-

plied to stainless steel. Combination

discs combine coated abrasive and sur-

face conditioning on the same backing

pad in an interleaf pattern, thus remov-

ing the weld and polishing at the same

time. Unitized discs consist of layers of

non-woven material impregnated with

abrasive grit. They are available in coarse

through fine grits and excel at producing

fine finishes on stainless steel welds.

Abrasive Belts

As previously discussed, belts are gener-

ally used to process larger material sur-

face areas. The two main categories of

abrasive belts used in stainless steel fin-

ishing are coated and surface condition-

ing.

Traditionally, zirconia-coated abrasives

belts were used for stainless steel fin-

ishing. However, the introduction of

newer ceramic grain belts caused a rise

in popularity of stainless steel finishing.

The newer ceramics offered by leading

coated abrasive manufacturers, such as

VSM Abrasives and Norton Abrasives,

require less pressure, last longer than

other coated abrasives, and cut cooler--

particularly important for stainless steel

finishing as heat generation is an obstacle

to effective finishing.

Belts made out of surface conditioning

are generally applied after the coated

abrasives do their work. The surface

conditioning belts texture more than

remove material. The belts generate the

appearance of a linear brushed finish on

the material.

When sequencing abrasives, fabricators

should work from coarse to fine. Skip-

ping more than one grade level when

moving finer in grit tends to give the

material an uneven choppy look. When

blending welds and

large surfaces, using

longer strokes will

result in a more even

appearance.

Power Tools

While the angle

grinder is still the

workhorse for stain-

less steel weld fin-

ishing, linear belt

finishing tools are re-

quired to achieve the

higher level stainless

steel finishes that are

more frequently be-

ing specified.

Power tools are available as pneumatic

or electric. Pneumatic tools offer the ad-

vantage of being lighter, and therefore,

easier for the operator to hold and han-

dle. On the other hand, electric power

tools offer the advantage of more power

and variable speed control.

The ability to control the speed of the

tool is essential for stainless steel finish-

ing. As the surface finish becomes finer,

the speed of the tool must be reduced

to achieve a uniform appearance in the

surface finish. Therefore, fabricators at-

tempting #4 finishes and finer, need to

have variable speed angle grinders and

linear belt finishers in their workshops.

By reducing finishing speeds as the sur-

face finish becomes finer, abrasive con-

sumption is also reduced resulting in the

need for fewer abrasives to complete the

project.

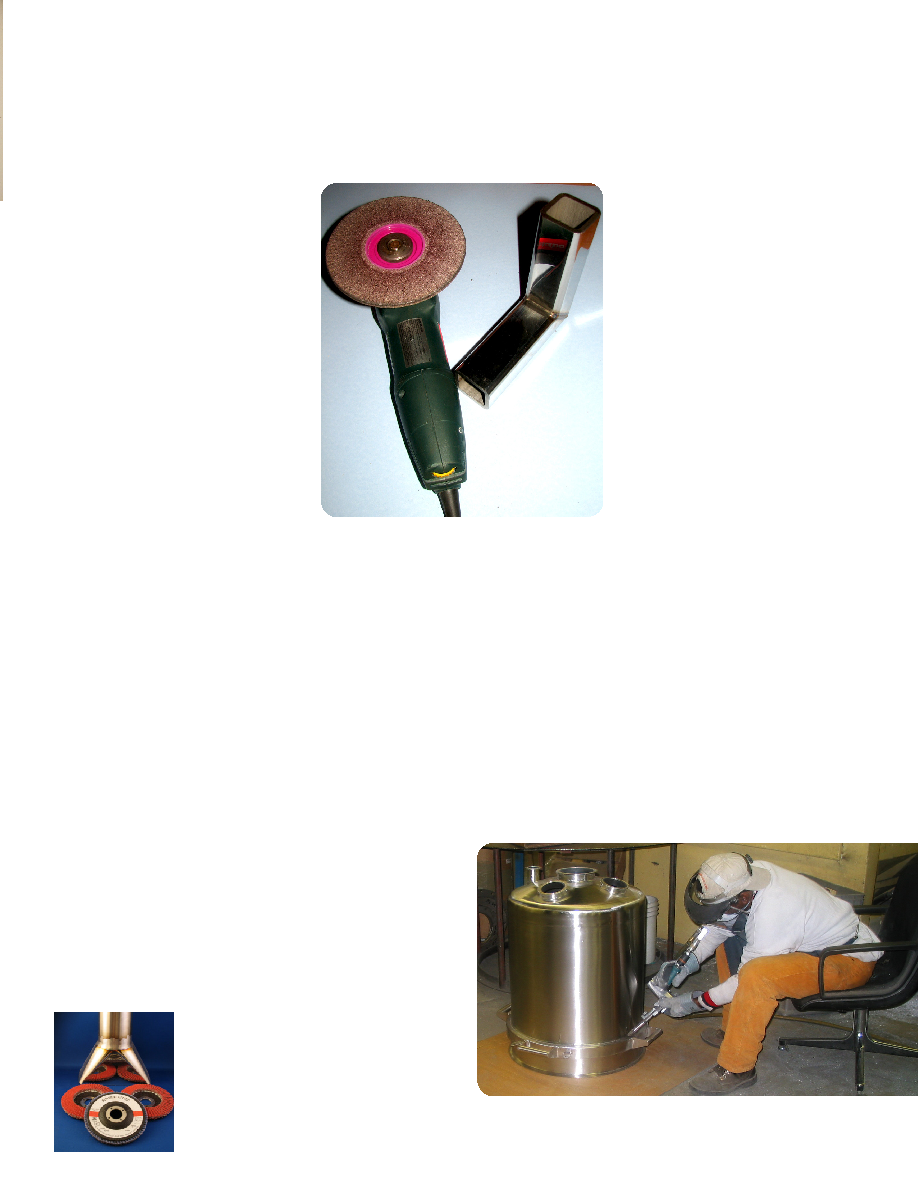

New grinders, such as the WE14-125VS

from Metabo, offer variable speed, vi-

bration reduction, quick wheel change

and a powerful 12 amp motor. The

yellow dial at the bottom controls the

speed. This 6" unitized disc must be run

at 3000 rpm (a normal grinder runs at

11000 rpm) and will grind and polish the

corner weld in a single step.

For linear finishing and blending welds

with adjacent pre-polished material,

When sequencing abrasives, fabricators

should work from coarse to fine.

speed vibration reduction.

used to remove

the weld in a

p r e - p o l i s h e d

stainless

steel

square to round

transition.

The Dynafile is ideal for hard-to-reach areas. They

are ideal for areas that can't be reached by a grinder

or polisher.

variable speed burnishing machines such as the

flex machine below, allow operators to more eas-

ily achieve desired finishes in stainless steel. It is

important to note that a linear scratch pattern

(frequently specified for stainless steel finishes)

cannot be achieved with an angle grinder. The

angle grinder will leave swirl marks in the mate-

rial. Only a burnisher, like the unit below, can

achieve the desired finish.

A relatively new class of power tool has been gain-

ing popularity for polishing pipe and hand rails.

The pipe sander

wraps 270 degrees

around the work

piece and quickly

accomleft: plishes

finishing

tasks

with ease. The

p r e - t e n s io n e d

arms apply even

pressure to the

workpiece pro-

ducing a uniform

finish.

The Dynafile is

another tool re-

quired for most

stainless steel finishing jobs. The tool accepts small

portable belts and excels at accessing hard to reach

areas. Dynafiles are typically used where access to

use the grinder or polisher cannot be gained.

The final step is to create the mechanical stain-

less steel finishing plan and execute completion

of the project. This involves pre-planning the

actual work steps involved in order to complete

the required finish. Each work step should list the

power tool, abrasive type and grit which will be

used.

Nowhere is preparing more important than in the area of mechanical pol-

ishing. By carefully planning the project, hours of needless re-work can be

avoided. If fabricators are attempting a finish they have not achieved in the

past, they may want to consult with their abrasives and power tool distributor

for guidance.

The following points should be considered during the planning process:

Ordering pre-polished material when possible.

Protecting the material with a plastic film coating.

When possible using TIG welding.

Minimize weld diameter and spatter.

Pre-polishing parts that have difficult access points.

Educate employees concerning care in material handling (stainless steel is

easily scratched).

Part in Finishing Process

In summary, the three steps critical to successful stainless steel finishing include

defining the customers, requirements, planning the sequence, which includes

choosing the abrasives and tools that will be used, and executing the plan. By

adopting this approach, fabricators can fulfill their customers' requirements in

the least time and with the least cost.

1.

2.

3.

4.

5.

6.

270 degrees around the

work piece.

step three

FINALIZE AND

EXECUTE THE PLAN

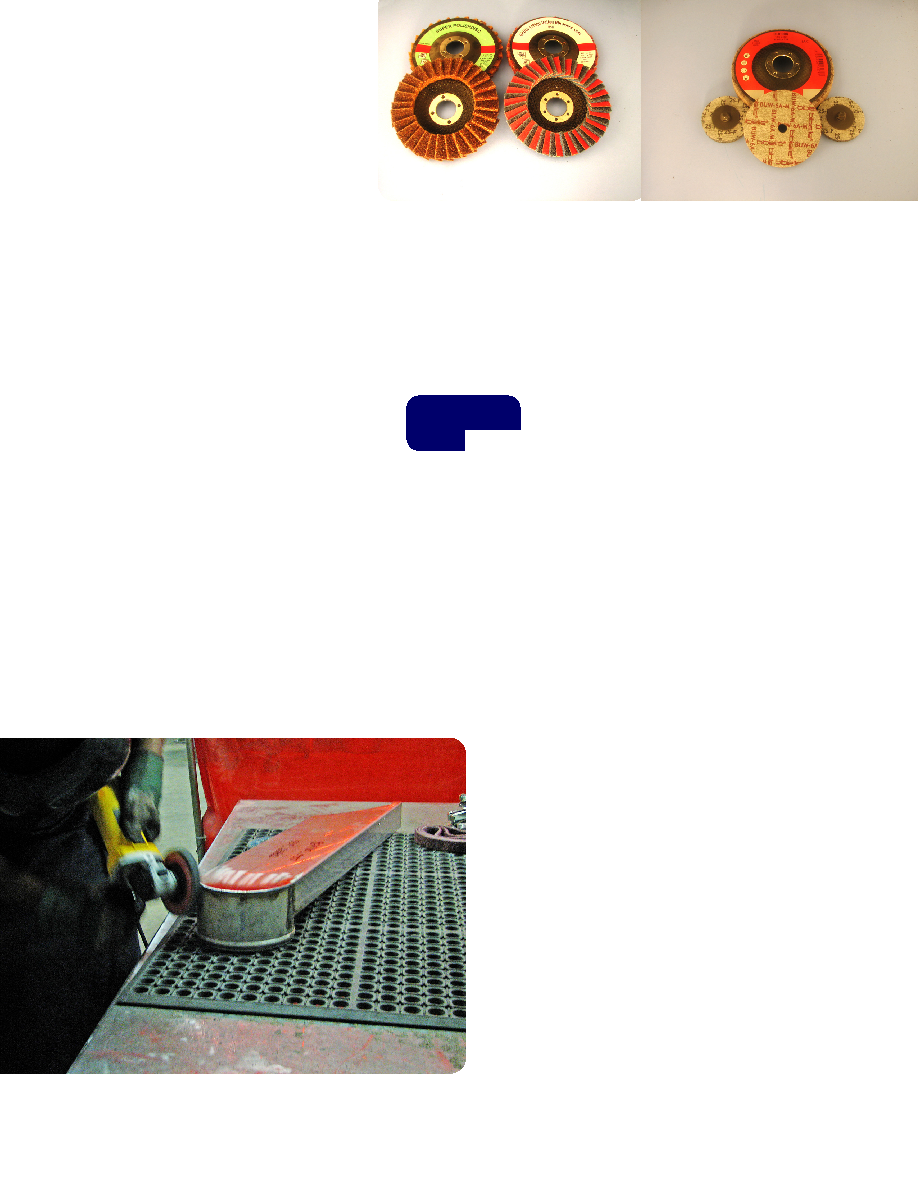

The inside of this part is pre-polished and protected with

platic film during the manufacturing process. The film is

peeled back at the welded seams.

Part in finishing process.

About the Author:

This article was printed in the September/October 2009

issue of Fabricator magazine.

For more information: