Over the last several years,

there has

been an explosion of new abrasives and

more powerful right angle grinders on

the market.Many of these products are

providing impressive results in cutting,

grinding and finishing tasks for many

industries, including metalworking. Ad-

ditionally, these products, when chosen

correctly for the task at hand, can reduce

both costs and finishing time.

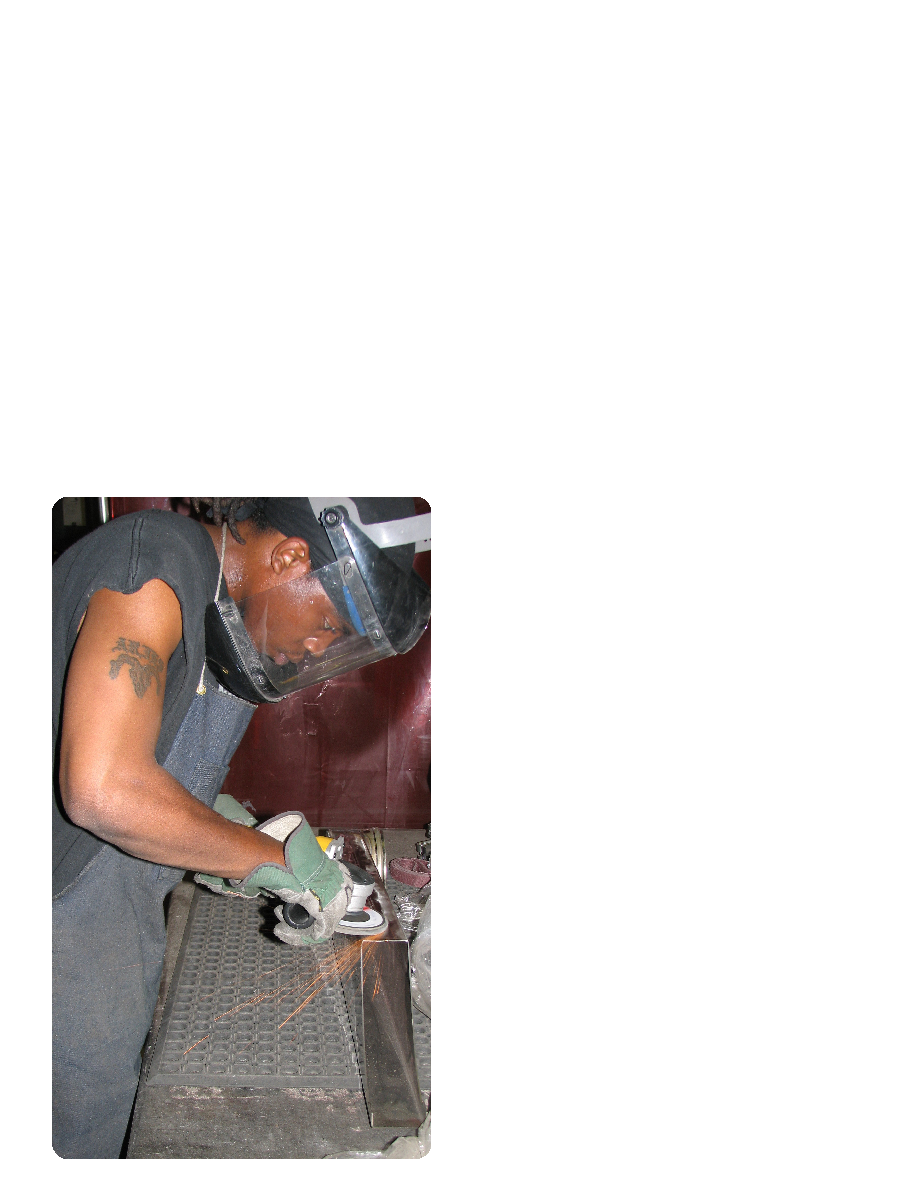

User-friendly improvements to

the right angle grinder

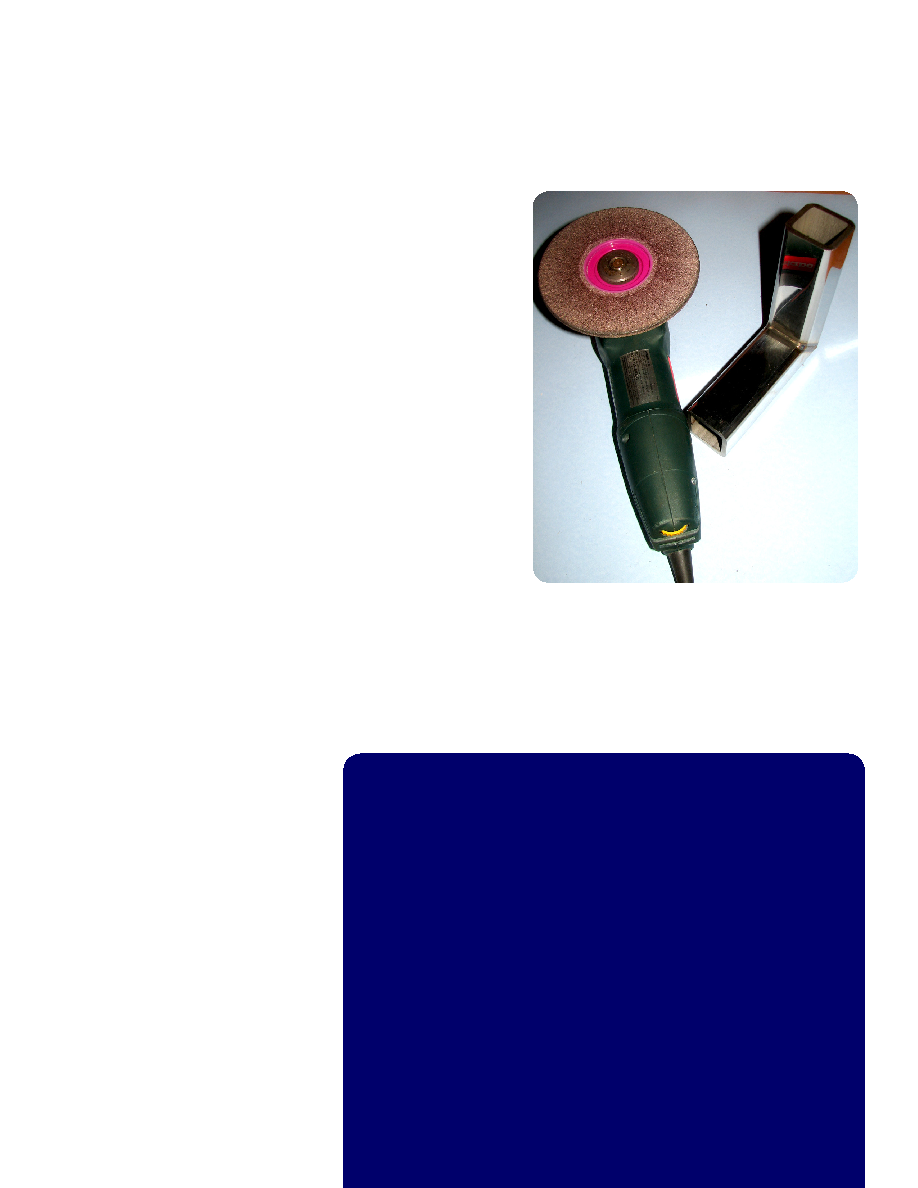

The right angle grinder is generally the

most widely used tool in any metalwork-

ing shop. New developments in

the grinder itself include more powerful

variable speed motors, improved ergo-

nomics, and vibration dampening de-

signs.

The newer grinders, when used to per-

form different tasks, allow the user to ad-

just the speed. This becomes especially

critical when changing from grinding to

polishing. Polishing at slower speeds al-

lows the operator better control over the

work piece and improves the aesthetics of

the final surface finish. In addition, stud-

ies have shown that altering the speed

of the grinder to the optimum level can

double the working life of the abrasive in

use.

For individuals who use

the grinder for a significant

amount of time each day,

new ergonomic vibration

dampening designs from

companies such as Metabo,

Fein, and Makita reduce

repetitive use injuries and

worker downtime. This is

because the vibration from the grinder is absorbed by the handle and not transferred

to the workers themselves. Also, the newer designs make the grinder lighter, thereby

reducing operator fatigue, and allow for optimum hand position while grinding.

The Latest Abrasives

BY CHRIS STONE

In the metal finishing arena, the right-angle

grinder is "king" of the hand-held power

tools.

For Your Information

Some factors that affect how quickly a substance is abraded in-

clude:

Difference in hardness between the two substances: a much

harder abrasive will cut faster and deeper. Grain size (grit

size): larger grains will cut faster as they also cut deeper.

Adhesion between grains, between grains and backing, be-

tween grains and matrix: determines how quickly grains are

lost from the abrasive and how soon fresh grains, if present,

are exposed.

Contact force: more force will cause faster abrasion. Loading:

worn abrasive and cast off work material tends to fill spaces

between abrasive grains so reducing cutting efficiency while

increasing friction.

Use of lubricant/coolant/metalworking fluid.

Source: Wikipedia

·

·

·

·

Flap dISCS

For material removal, including weld

grinding, blending, and deburring, again

the angle grinder is still the workhorse of

most metalworking shops.

In most material removal operations, the

old two-step process of grinding wheel

and then fiber disc finishing has been re-

placed with the advent of the flap discs.

Flap discs grind and finish in one step,

thereby reducing both finishing time and

finishing costs. In addition, by using a

variable speed grinder and flap disc, the

user can further extend by 50 percent the

working life of the flap disc by keeping

the rpm between 5000 and 8000.

Advantages of the flap disc include:

Grinds and finishes at the same time,

saving both time and money.

Removes material aggressively. Its

removal power is equal to that of the

depressed center wheel, but it works

more safely and offers a better-fin-

ished surface.

Has a lightweight design to reduce

operator fatigue.

Is easy to use and requires very little

surface pressure.

Its especially cool cutting permits

light contouring and avoids burning

the work piece by overheating.

Lasts up to 30 times longer than

conventional fiber discs due to their

overlapping flap construction.

Assures consistent performance as

new particles re continually exposed

during the life of the product.

Due to its tough construction, allows

for aggressive edge grinding.

The quality of flap discs varies greatly

from manufacturer to manufacturer.

When choosing a flap disc vendor, the

purchaser should look for two distinc-

tions: the type of coated abrasive; and the

manufacturer of the coated abrasive flaps,

which are glued to the backing of the flap

disc.

·

·

·

·

·

·

·

·

Requires less force for cutting

Reduces base material loss during

the cutting operation

Generates less heat

Improves surface finish on the cut

material

These higher quality wheels use a mix-

ture of aluminum oxide and zirconia

grains to improve cutting life, along with

reinforced layers of mesh, which provide

added strength to the disc.

When working with stainless steel or

other high nickel alloys, the user should

be sure that the cut off

wheel issulfur and chlo-

ride free, which will

prevent contamination

of the work piece. It is

important to choose a

wheel from a reputable

manufacturer and use

the proper guards and

flanges when cutting,

as an inferior wheel

can easily blow apart in

the thinner design and

present a hazard to the

operator. The new cut

off wheels can be found

in diameters ranging

from 3 to 7 inches and

thicknesses of .035 to

.045 inches.

·

·

·

·

CuT OFF wHEElS

When cutting with a right angle grind-

er, the latest advent of thinner slicing

cut off wheels allows faster cutting with

less material loss. The new, thinner de-

signed, type 1 wheels minimize the sur-

face area contact between the material

and the wheel due to the reduced sur-

face width of the wheel. The reduced

surface cutting area provides the follow-

ing benefits:

When choosing a flap disc vendor, the purchaser should

look for two distinctions: the type of coated abrasive; and

the manufacturer of the coated abrasive flaps, which are

glued to the backing of the flap disc.

Clean

and strip

discs

clean

metallic

surfaces

without

material

removal

(LEFT)

.

TYpE OF COaTEd aBRaSIvE

Characteristics of different types are appropriate

to different applications:

Aluminum oxide is suitable to

most general purpose applica-

tions and is specified for use on

wood and most metals.

Zirconia Alumina grains are

both sharp and durable, pro-

viding fast stock removal and

longer life. They are used to

greatest advantage in coarse

grits on heavy-duty metal-

working stock removal appli-

cations. Zirconia will generally

last twice as longs as Alumi-

num Oxide material.

Ceramic grain series are spe-

cial products for aggressive and

cool grinding. These abrasives

ensure faster grinding while at

the same instance offer better

surface quality and excellent

stock removal rates. The cool

grinding properties ensure an

extension of the service life

and prevent surface discolor-

ation. Ceramics are specifi-

cally applicable for grinding

high alloyed steels, titanium,

nickel alloys and all extremely

hard materials. Ceramics will

generally last 50 percent longer

than Zirconia material.

COaTEd aBRaSIvE FlapS

maNuFaCTuRERS

For all intents and purposes, there are no lon-

ger any U.S. companies manufacturing coated

abrasives. The best material is supplied by

leading European companies such as Nor-

ton (French), VSM (German), and

Klingspor (German). Caution is advised

when purchasing coated abrasives,as there

are inferior products being manufactured in

the Far East that might cost less, but will not

last very long when put into use.

Other factors that figure into the life of the

flap disc include the durabilityof the backing

(either fiberglass or nylon) and the number

of flaps laid on the disc. Higher quality discs

use extra layers of both fiberglass backing

and coated abrasives flaps.

good

About the Author:

Chris Stone is owner of lehigh valley abrasives,

supplier of abrasives and power tools for metal working.

lehigh valley abrasives originated in 1967 as a fabricator

of stainless steel tanks, vessels, and hoppers for the food,

pharmacuetical, and chemical industries. The demand

from customers for improved surface finishes led to the

company's development and manufacturing of flap discs,

belts, and cut-off wheels.

This article was printed in the September/October 2007

issue of Fabricator magazine.

For more information:

Finally, due to the prevalence of right angle grinders in the workplace, a

number of newer abrasive products tailored to cleaning and finishing have

been adapted for use on the grinder. They include:

-- These discs clean metallic surfaces without

material removal. They are a safer alternative to wire brushes. The primary

applications for clean and strip discs include:

Removal of paint and adhesives

Cleaning of weld seams

Removal of welding scale and discoloration

Surface preparation for auto body work

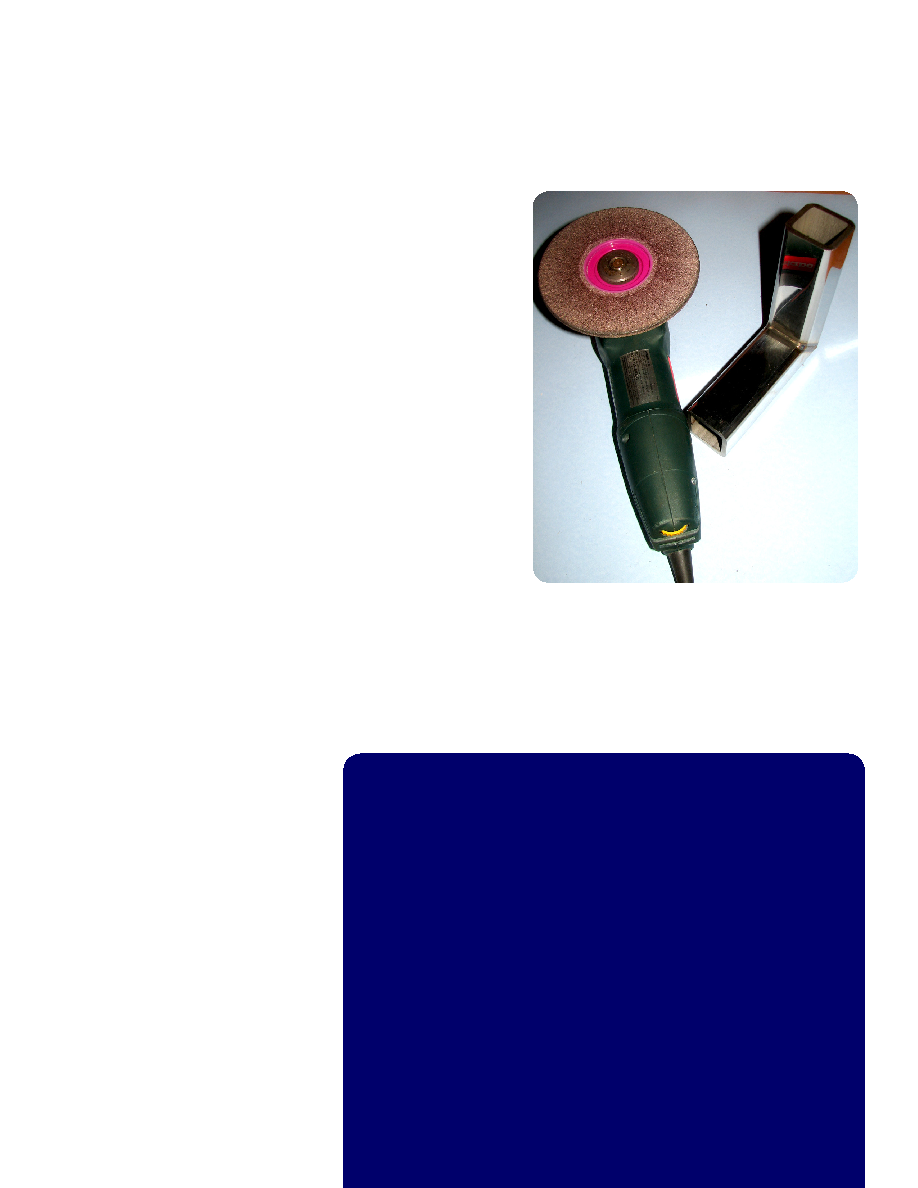

-- Surface

conditioning discs are composed of open nylon webbing, impregnated with

abrasive grains. They offer a continuous and controlled finish with minimal

material removal. Also, they are flexible in nature and allow polishing of con-

toured surfaces. Surface conditioning products are used heavily in the stain-

less steel fabrication industries for providing a satin finish to the

base material and welds. Additional applications include:

gasket removal

coatings removal

cleaning weld splatter

removing heat discoloration

Graining stainless steel sheet

Type 27 unitized wheels are an excellent choice for the final polishing step

on stainless welds as they blend tool marks, remove surface imperfections

and leave a bright clean finish on stainless steel, titanium, and aluminum.

The unitized wheel is composed of layers of non-woven material, impreg-

nated with abrasive grain and pressed together into its final shape. The unit-

ized wheel design allows for edge grinding and access to weld joints that

sometimes cannot be reached with a flap disc.

The advent of new abrasives and changes to the right angle grinder allow

the user to accomplish most finishing tasks with a single right angle grinder.

Newer abrasive materials last longer, provide an improved surface finish, and

get the job done faster and at a lower total cost. And finally, the newer angle

grinders are more powerful and safer due to improved ergonomics.

The latest developments and improvements allow the right angle grinder

to maintain its role as the king of the hand held power tool in the metal

finishing arena.

·

·

·

·

·

·

·

·

better

best